Additive manufacturing innovation for musculoskeletal tissue repair and regeneration: from bench to bedside

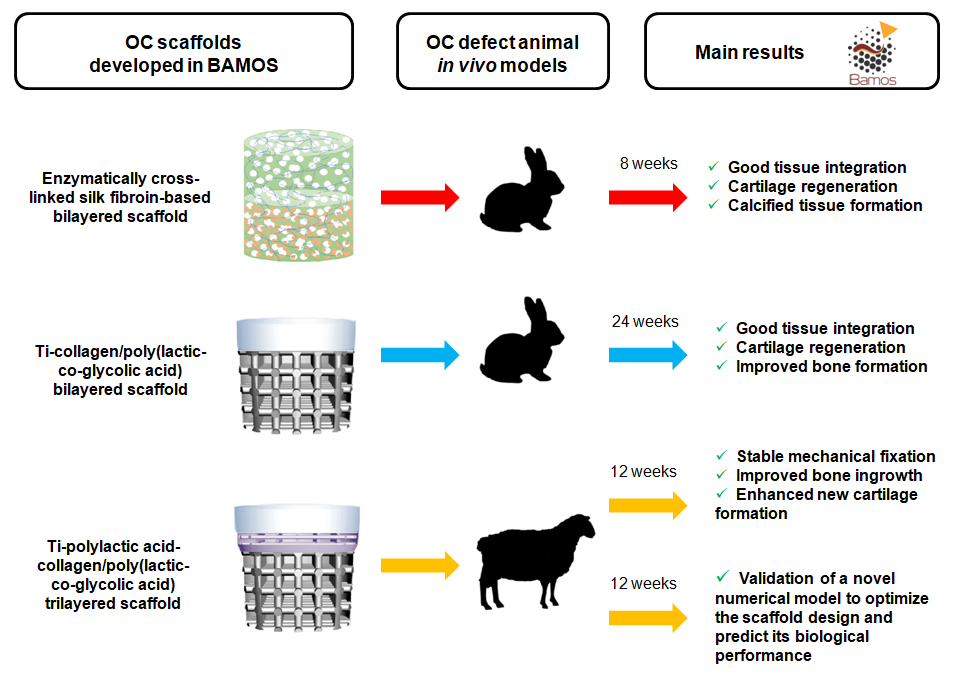

Translation through collaboration: practice applied in BAMOS project in in vivo testing of innovative osteochondral scaffolds

Three-dimensional bio-printing of decellularized extracellular matrix-based bio-inks for cartilage regeneration: a systematic review

Additive manufactured polyether-ether-ketone implants for orthopaedic applications: a narrative review

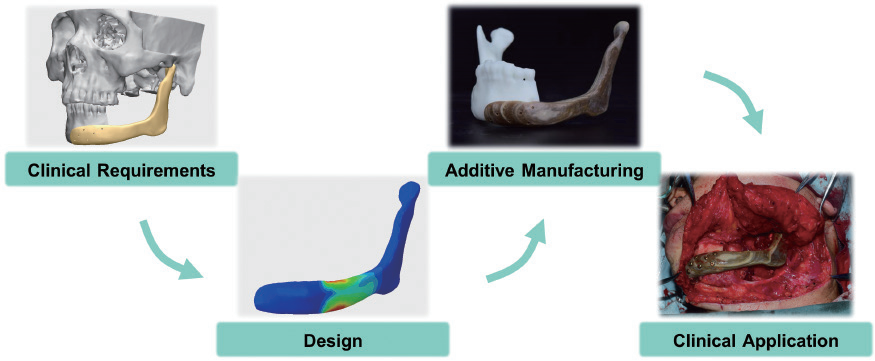

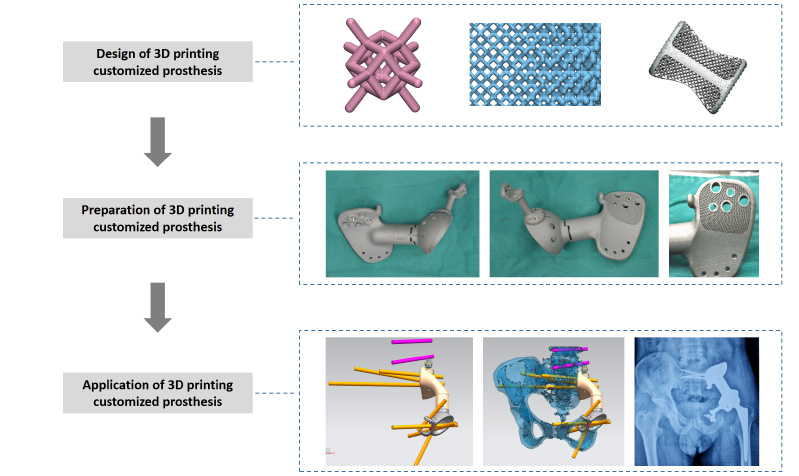

Three-dimensional-printed titanium prostheses with bone trabeculae enable mechanical-biological reconstruction after resection of bone tumours

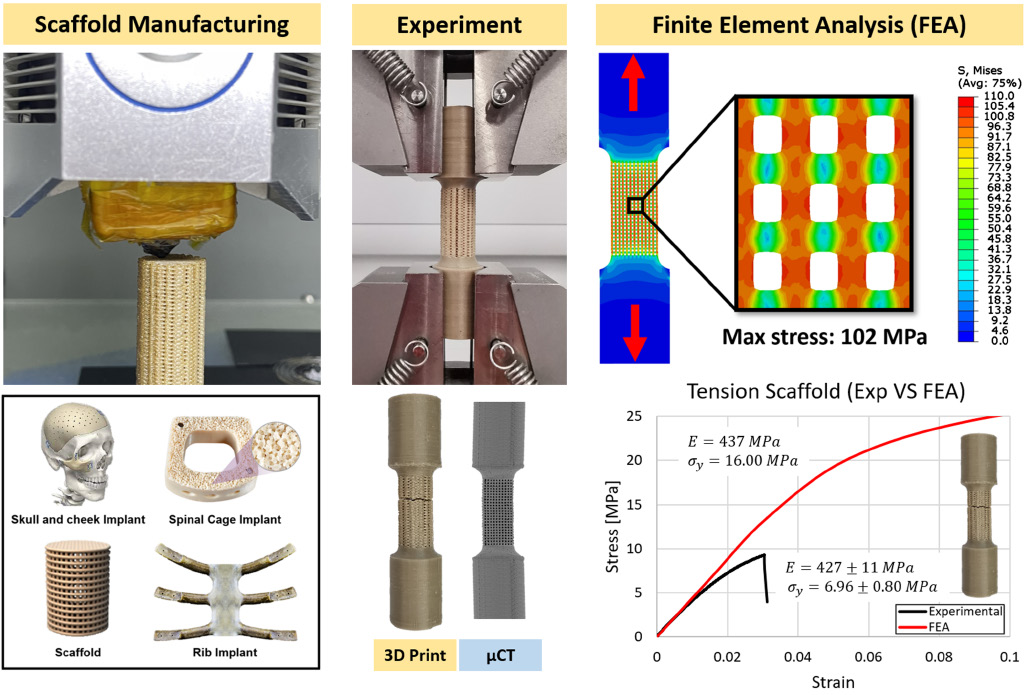

On the mechanical aspect of additive manufactured polyether-ether-ketone scaffold for repair of large bone defects

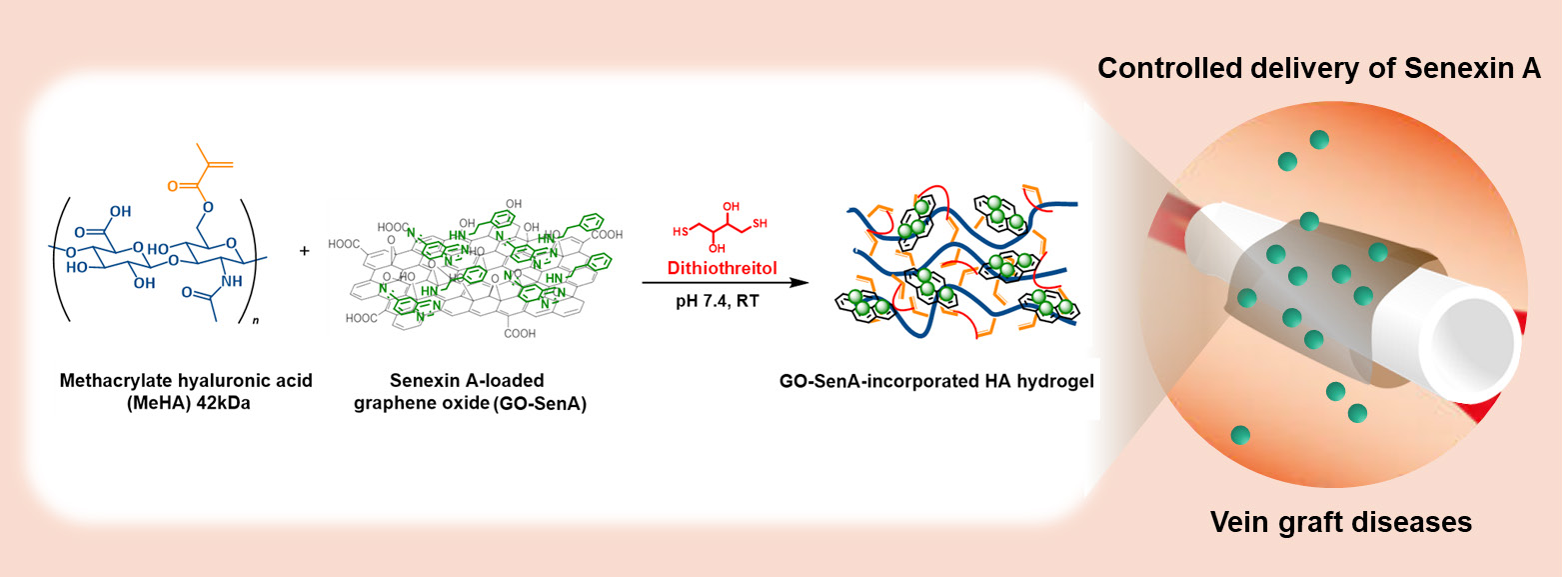

Graphene-incorporated hyaluronic acid-based hydrogel as a controlled Senexin A delivery system

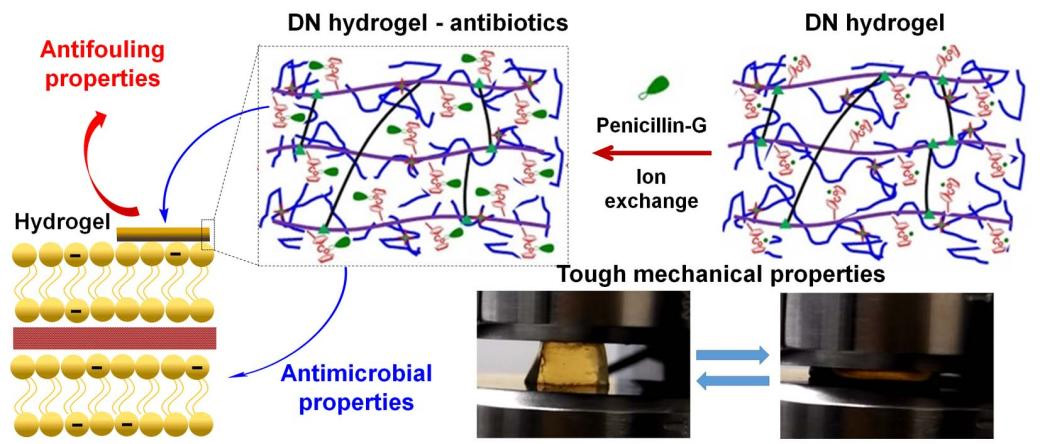

Antifouling and antimicrobial cobaltocenium-containing metallopolymer double-network hydrogels